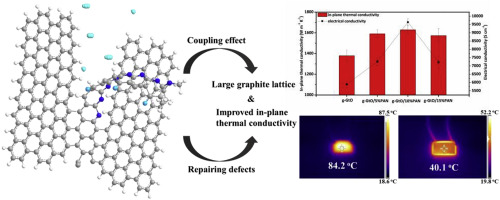

Graphene film has potential to act as an excellent heat dissipation material. However, its thermal conductivity suffers from some limitations, including small graphene lateral sizes and low production efficiency from a practical viewpoint. To solve these issues, we propose an industrially viable protocol to synthesize homogeneously oxidized graphite oxide (GtO) with large lateral sizes and easy-purifying features. We employ polyacrylonitrile (PAN) as a coupling agent to repair the defects on GtO sheets and link these sheets together during the annealing treatment. The graphitized GtO/10%PAN film (g-GtO/10%PAN) shows excellent thermal and electrical properties, with an in-plane thermal conductivity of 1629.24 ± 43.88W m-1K-1and an electrical conductivity of 9645.29 ± 199.44 S cm-1. Furthermore, it also exhibits outstanding flexibility; the original thermal conductivity can be maintained after 20,000 times bending. The g-GtO/10%PAN film offers an alternative to replace commercially used graphitized polyimide (PI) film. Our research provides a general method for the fabrication of high quality graphene film.

This work has been published on Carbon, see details:

Ke Wang, Mengxiong Li, Hongbin Lu, Polyacrylonitrile coupled graphite oxide film with improved heat dissipation ability. Carbon, 2019, 144, 249-258. Link